Cardboard or Plastic? Differences Between Lithography vs Offset Printing

Customized printed boxes are a cost-effective and efficient way to increase your business brand, bring attention to your brand, and aid consumers in easily recognizing your products. Customized boxes instantly place your brand at the forefront of your consumer’s mind and place your business at the top of their list. When people shop, they look for what you have to offer, not what you have to sell. With custom printed boxes to display your items, you will not only be providing a feature for showcasing your product, but also something that helps consumers recognize what you are selling. This is an important aspect of marketing because when people know who you are, they are more likely to do business with you.

When it comes to printing box options, there are many different types of custom printed boxes to choose from. The traditional cardboard material is still available, but there are new eco-friendly and recyclable options on the market today. Whether you choose corrugated cardboard or the newer eco-friendly alternative, there is something out there for your business. These eco-friendly boxes do not contain plastic or petroleum, which can harm the environment. You can also find custom printed boxes that are made of recycled cardboard and paper, which are both cost efficient and convenient for consumers. If you are a business that sells food items, then you can save money on printing costs by ordering cardboard boxes made from recycled material.

Your next option for custom printed boxes is to order blank, unpolluted cardboard stock. The most affordable method for printing your own box, this material will have your logo or company name imprinted on it. Because blank cardboard has no color, it is the perfect choice for printing your custom logo on. This is also great if you are thinking about using your logo on your envelopes or promotional materials. It is the least expensive option for custom printed packaging boxes.

If you want to save even more on product packaging, then you can purchase recycled boxes that can be reused for more purposes. The problem with this solution is that you are limited to using the same logo or design on each recycled box that you purchase. This might not be as easy as ordering custom printed packaging boxes. You could have the benefit of using the same logo on all of the boxes, but you would have to order them in bulk. However, if you are unable to source the exact number of boxes that you need, you could always have the stock inventory available for your use.

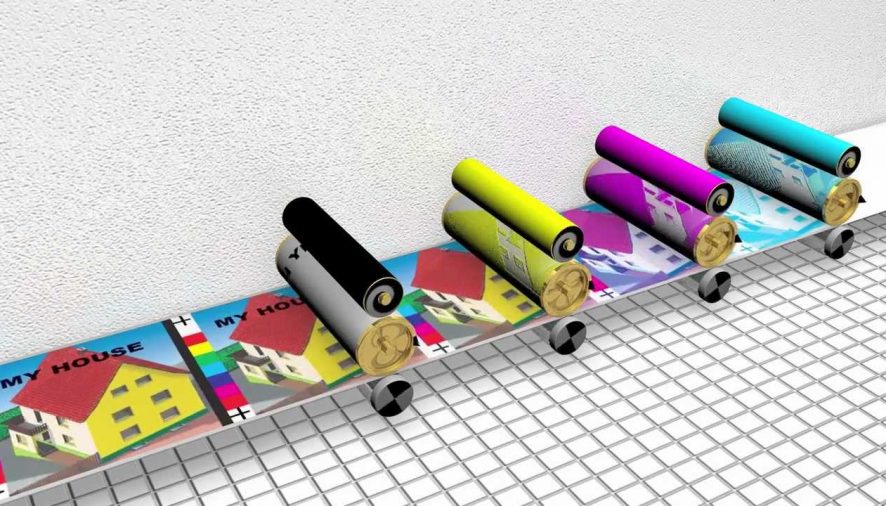

If you need a lot of branding printed boxes to get your message across, then you might consider offset printing for your needs. When you buy large quantities of printed boxes, you can receive a discount on the cost. Plus, offset printing offers a higher quality image than traditional lithography, which means that you will see an increase in your brand recognition. This is because you will be using high quality paper that will last longer.

There are a number of different ways that you can reduce the cost of product packaging. However, you do not want to skimp on the quality of the product. If you look at cardboard boxes versus plastic, or lithography versus offset printing, you will quickly see that the difference between the most affordable option and the most expensive one is the quality of the materials. If you want to make a big impact on your customer’s mind, you should make sure that you invest in printed boxes in large quantities. With the right branding and a good marketing plan, you can start your own business and increase your profit margin when it comes to your product packaging.