Metal injection molding emerged from a simple yet profound question that haunted materials scientists in the mid-twentieth century: could the elegant simplicity of plastic moulding be married to the enduring strength of metal? The answer, when it finally arrived, transformed not just manufacturing but our very understanding of what shapes metal could assume. It is a process that begins with powder fine as talc and ends with components harder than stone, a metamorphosis as remarkable as any found in nature. What lies between these two states is a carefully choreographed dance of chemistry, physics, and engineering that reveals something fundamental about how matter can be coaxed into new forms.

The Poetry of Powder and Polymer

At its heart, Metal injection molding begins with an unlikely marriage. Metal powder, ground to particles measuring mere micrometres, is blended with thermoplastic binders to create a feedstock that flows like honey when heated. This combination defies our intuitive understanding of materials. Metal should be rigid, immutable, resistant to change. Yet mixed with the right polymers in the right proportions, it becomes fluid, compliant, willing to fill the most intricate cavities of a mould.

The powder itself carries a history. Each particle was once part of a larger mass, atomised through gas or water jets, or reduced through chemical processes that strip oxygen from metal oxides. The particle size matters enormously. Too large and the powder will not pack efficiently. Too small and the particles clump together, refusing to mix properly with the binder. The sweet spot lies between ten and twenty micrometres, a dimension invisible to the naked eye yet critical to everything that follows.

The Architecture of Transformation

The injection process unfolds in stages, each one essential to the final outcome. The feedstock enters a heated barrel where screws compress and heat the mixture to temperatures around 150 to 200 degrees Celsius. The material softens, becomes pliable, and under enormous pressure flows through narrow gates into the mould cavity. In seconds, the shape is formed, capturing every nuance of the tool’s interior surfaces.

But this green part, as manufacturers call it, remains mostly polymer. The metal particles sit suspended in a matrix of binder, touching but not yet bonded. What emerges from the mould is fragile, a ghost of what it will become. Singapore’s Metal injection molding industry has refined this initial stage to remarkable precision, producing green parts that serve as faithful templates for the transformations to come.

The Ritual of Removal

Debinding represents the first great transition. The polymer that made the metal flow must now be removed, extracted through processes that seem almost alchemical in their precision:

- Solvent debinding dissolves the binder through chemical reaction, leaving a porous brown part held together by capillary forces

- Thermal debinding burns away the polymer in controlled atmospheres, preventing oxidation whilst allowing gases to escape

- Catalytic debinding uses gaseous acids to break polymer chains selectively, removing the binder whilst maintaining part integrity

Each method has its devotees, its particular advantages and constraints. The choice depends on part geometry, production volume, and the specific feedstock formulation. What matters is that the binder must leave without disturbing the careful arrangement of metal particles, without causing cracks or distortions that would render the part useless.

The Fire of Fusion

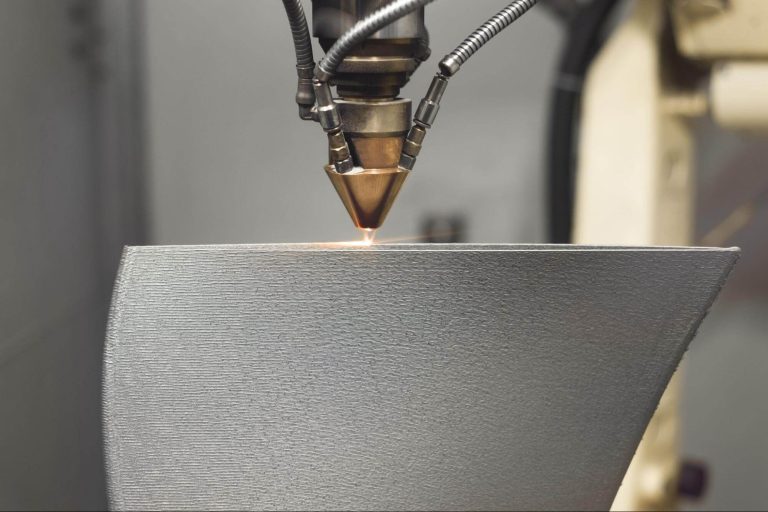

Sintering transforms the fragile brown part into solid metal through heat that approaches, but never quite reaches, the melting point. At temperatures between 1,200 and 1,400 degrees Celsius, depending on the alloy, something miraculous occurs at the atomic level. Atoms begin to migrate across particle boundaries. Necks form where particles touch. Pores close as material flows into empty spaces. The part shrinks uniformly, densifying until it achieves ninety-six to ninety-nine per cent of the theoretical density of fully wrought metal.

This is not melting. The particles never lose their solid structure entirely. Instead, diffusion drives the consolidation, atom by atom, creating metallurgical bonds as strong as any forged or cast component. The microstructure that results shows grains typical of processed metals, with properties that match or exceed those of conventionally manufactured parts.

The Spectrum of Possibility

Metal injection molding accommodates a remarkable range of materials, each bringing its own character to the final component:

- Stainless steels offering corrosion resistance and biocompatibility

- Tool steels providing hardness and wear resistance

- Titanium alloys delivering strength at minimal weight

- Magnetic alloys enabling electromagnetic applications

- Refractory metals withstanding extreme temperatures

The applications span industries. Medical devices require the biocompatibility and precision that Metal injection molding delivers. Electronics demand the dimensional accuracy and electromagnetic properties. Automotive systems need the reliability and consistency. Each sector has discovered that certain shapes, certain combinations of features, become possible only through this process.

The Human Dimension

What makes Metal injection molding significant is not merely its technical capabilities but what those capabilities enable. A surgeon operates with instruments shaped precisely for their purpose. A smartphone connects us across continents using components manufactured to tolerances measured in thousandths of millimetres. An aircraft flies safely because sensor housings maintain their integrity under extreme conditions.

The process has democratised complexity in metal components. What once required master craftsmen or expensive multi-axis machining now flows from moulds in quantities that make sophisticated designs economically accessible. Singapore’s Metal injection molding facilities serve this democratisation, producing components that find their way into devices and systems that touch millions of lives.

The Continuing Evolution

The boundaries continue to expand. Researchers explore new alloys, investigate multi-material components, push the limits of size and intricacy. Yet the fundamental principle remains: metal powder and polymer combined, shaped through injection, refined through heat. Metal injection molding stands as testament to human ingenuity, transforming granular matter into precision components through processes that honour both the material’s nature and our need for forms that serve.